Wire Rope Hoist and Chain Hoist.

Wire rope hoist or chain hoist ? Of course, we have thought about this when we are required to choose one of the two types of hoists that are widely available on the market. Although both are used to lift goods, there are some differences for our references in choosing the type of hoist that suits to our needs. The following are the differences, advantages and the drawback of wire rope hoists and chain hoists.

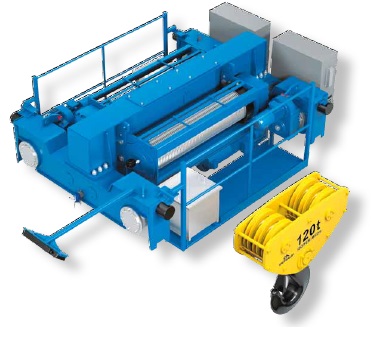

Wire Rope Hoist

We often find this type in the manufacturing, warehousing, construction, power plant and mining industries. This hoist uses a wire rope (sling) that is attached to a drum connected to a motor and gearbox so that it able to rotate and move the load up and down. To hold the load to stays hanging at a certain height, brakes are used which will function when the power supply to the hoist motor is off or cut off.

Wire rope hoists are generally produced with standard capacities from 1 ton to 80 tonnes. A special design is required to make a hoist with a capacity above 80 tons in order to get the hoist specifications that match with our need. This type consists of stationary, monorail, and double girder hoists. Monorail hoists are generally produced with a capacity under 15 tons while double girder types are made up to 250 tons or more.

Compared with a chain hoist, the wire rope hoist is relatively better when used in a large area and requires an equipment that will be used frequently. This is possible because this type can be produced from Light, Medium, Heavy and Very Heavy Duty Class. Compared with the chain hoist which is generally limited to Light Duty. The classification of hoist is based on the FEM / ISO Class which is determined based on the frequency of routine use in a day, as well as the average weight of the load that lifted when compared to the maximum lifting capacity.

With its various advantages, it turns out that the wire rope hoist also has disadvantages when compared to chain hoist. Here are the drawbacks:

- With a more complex system, the price will be more expensive.

- Not effective when using a manual trolley.

- Requires a power source or electricity.

- The size is relatively bigger than the chain hoist.

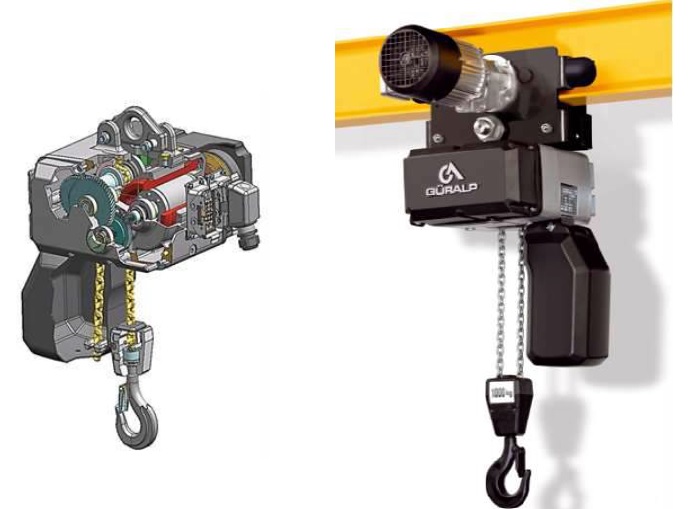

Chain Hoist

Chain hoists are very effective used in workshops, factories, small workshops and as standby maintenance cranes at water treatment stations. This type uses a chain that able to move up and down manually or with an electric motor. Because it can be operated manually, chain hoists are widely used in areas where there is no power or electrical source. In manual hoist, its compact shape makes it easy for us to move it from one place to another.

The drawbacks of a chain hoist are:

- Relatively has smaller lifting capacity.

- The lifting height is limited, or shorter than the wire rope type.

- Lower lifting speed.